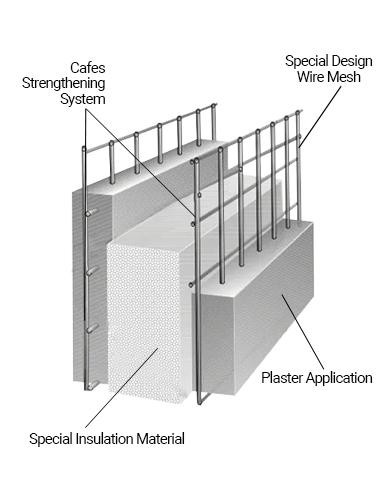

WHAT IS RIBAT PANEL?

RibatPanel®, which sets out with the slogan of build fast, build safely, build environmentally friendly while protecting nature, allows you to offer faster, more durable, more economical, more comfortable and more environmentally friendly solutions for your construction projects with much less labor and in a shorter time. 3D steel cage panel technology, which has been used in the world for nearly 60 years and offers reinforced concrete strength and steel lightness; is produced in Turkey with RibatPanel® wall, floor and roof system. RibatPanel® is a building system with high mechanical capacity and low seismic load in earthquakes, which allows the construction of buildings that can withstand earthquakes and hurricanes, and also have high thermo-acoustic insulation and high fire resistance. Since the RibatPanel® system cooperates in absorbing horizontal forces; it is an ideal building element for building buildings with high earthquake resistance capacity.

TECHNICAL INFORMATION

Details

OUTER MESH

The flexible and strong exoskeleton of the panel consists of gridded steel mesh with a diameter of 2.5 mm and a spacing of 5 cm x 5 cm, located on both sides.

CROSS LINES

Dip galvanized wire with 650-750/m² tensile strength and 3mm diameter connects the meshes on both sides to each other with a special braid.

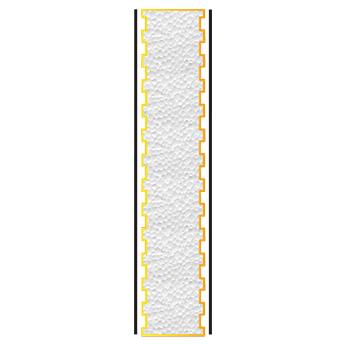

INSULATION BOARD

Inside the steel cage, there is a special EPS panel with a density of 16kg/m³ and a thickness of 8.5cm, with a corrugated structure that helps keep the plaster fast.

The standard dimensions of a Ribat Panel feature external mesh openings of 5cm x 5cm, with 1102 weld points per square meter and 110 cross wires. Panels are available in dimensions of 120cm x 600cm with thicknesses of 7.5 cm, 10 cm, and 12.5 cm, containing EPS foam. Custom production can be done according to project specifications by modifying all features such as wire thickness, external mesh openings, panel height, and thickness.